Company

Brembo is now a fully fledged multinational with operations in three continents and production facilities in twelve countries. It also has commercial branches in Sweden, France and Germany and markets its products in a remarkable seventy nations worldwide. The group has a workforce of around 7000 employees, approximately 10% of whom engineers and product specialists engaged in vital research and development activities. Each year, new human and manufacturing resources are taken on by the different Brembo branches around the world, especially in emerging and developing markets. The primary goal of Brembo's strategy of international expansion is to establish a presence in the countries where the group's main clients have production plants, so that its products may be supplied more rapidly and more efficiently.

Website

Showcase

![]()

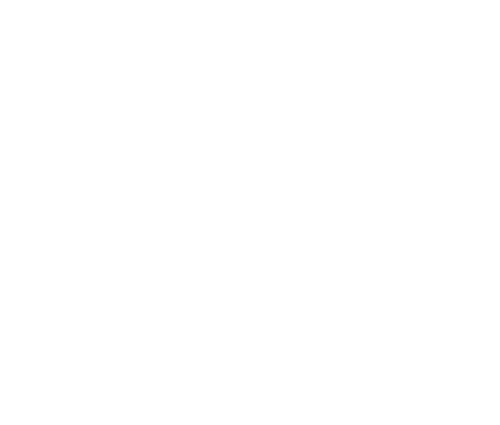

Brembo currently offers (3) different brake upgrade systems.

The difference between the Brembo GT System, the Brembo GTR System and the new Brembo Auto Race Systems will be detailed below. The GT Systems are designed for street use and extensive track use, while the GTR Systems are the ultimate in track/race brakes that are approved for street use and the Auto Race Systems are for track use only.

GT Systems, GTR Systems & Auto Racing Systems use the same Brembo Racing 2-Pc Disc Assemblies with the McLaren Anti-Rattle Float Hardware.

- The Auto Racing Systems only use the 72 Vane heavy disc for greater thermal capacity, while this is an option for some GT or GTR Systems.

- Only the Auto Racing Systems use the Type V Slotted Wide Annulus Endurance Race Disc

GT Systems, GTR Systems & Club Racing Systems use Goodridge Braided Stainless Steel Lines and aerospace grade materials for the Bells, Brackets and Hardware.

![]()

Please Contact For Applications and More Information

- Cast Aluminum Calipers

- Quick to Mass Produce

- Easy to Machine during fabrication

- Exceeds material stress requirements for street use

- High Quality Painted finish

- Quick to Mass Produce

- Unlimited color options

- Easy to correct or repair

- Dust Boots and High Pressure Seals

- TUV Approved for Street Use

- European Agency Corrosion Tests to Failure before approval for street use

- Street, Track and mild Race Use

![]()

Please Contact For Applications and More Information

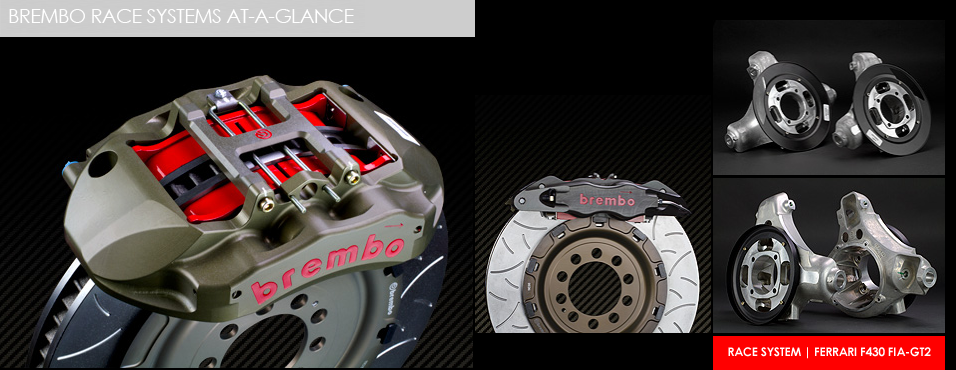

- Billet Aluminum Monobloc Calipers

- Individual Calipers are machined from billet aluminum > > Slow to Mass Produce

- Tougher material means slower to machine and fabricate

- Stronger material for greater stresses in race environment

- Nickel Plated for greater Thermal Protection

- Costly and slow finishing process

- Expensive materials used in finishing process

- Only Nickel Plate finish available

- Stainless Steel Piston Inserts for greater Thermal Protection

- Slow & Exact machining required to produce

- Expensive material to machine

- Extra components not found in GT System Calipers

- Dual Pressure Seals

- Slow & Exact machining required to produce groove deep in caliper body

- TUV Approved for Street Use

- European Agency Corrosion Tests to Failure before approval for street use

- Street, Track and Full Race Use

![]()

Please Contact For Applications and More Information

- Cast Aluminum Calipers

- Quick to Mass Produce

- Easy to Machine during fabrication

- Exceeds material stress requirements for street use

- Hard Anodized for greater Toughness

- Easy finishing process

- Finished Look not an issue or important

- Only Hard Anodized finish available

- Stainless Steel Piston Inserts for greater Thermal Protection

- Slow & Exact machining required to produce

- Expensive material to machine

- Extra components not found in GT System Calipers

- Single Pressure Seals

- Race Use Only

- Track and Full Race Use Only

![]()

Brembo Upgrade with Slotted Rotors